Seeing is believing.

Welcome to our TOMRA video channel. Browse, share and embed videos from the TOMRA universe!

If you don’t want to miss any new video, please subscribe to our video channel.

Aluminum Sorting - 99% Purity Levels - Case Study New X-TRACT™ - Sub Eng

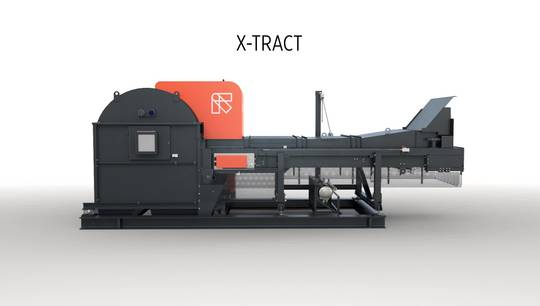

Increase purity rates of up to 99% on scrap metal products that would otherwise go into secondary remelts with TOMRA’s new high-speed x-ray transmission (XRT) technology.

Discover the new generation X-TRACT™ for aluminum sorting: www.tomra.com/xtract

TOMRA is a global leader in aluminum recycling and processing with XRT sorting systems installed in 34 countries. Our newest generation X-TRACT™ machine features groundbreaking technologies that accelerate the production and increase the purity of aluminum fractions.

With increased belt speeds up to 3.8 meters per second and increased capacity per meter width, the new X-TRACT™ accelerates the recovery of low-carbon aluminum and valuable secondary metals like copper. By separating aluminum from super lights and heavy metals at high throughput speeds, new X-TRACT™ also enables operators to adjust sorting to their needs and input material.

The XRT sorting machine’s powerful precision in detecting aluminum alloys, upgrading zorba and separating magnesium fractions to create furnace-ready aluminum. Scrap metal recyclers and smelters alike can profit from TOMRA’s in-house developed mechanics, sensors and software that maximize yields and purity levels.

In this video, our customer Alutrade reveals the extraordinary results they have achieved with the new X-TRACT™. As the largest UK independent aluminum recycler, the company processes more than 42,000 metric tons of aluminum scrap per year. Whether recycling aluminum cans, manufacturing scraps (extrusions) or zorba processing, the new generation X-TRACT™ is the ideal sorting system for peak performance.

Explore now: www.tomra.com/xtract

Discover the new generation X-TRACT™ for aluminum sorting: www.tomra.com/xtract

TOMRA is a global leader in aluminum recycling and processing with XRT sorting systems installed in 34 countries. Our newest generation X-TRACT™ machine features groundbreaking technologies that accelerate the production and increase the purity of aluminum fractions.

With increased belt speeds up to 3.8 meters per second and increased capacity per meter width, the new X-TRACT™ accelerates the recovery of low-carbon aluminum and valuable secondary metals like copper. By separating aluminum from super lights and heavy metals at high throughput speeds, new X-TRACT™ also enables operators to adjust sorting to their needs and input material.

The XRT sorting machine’s powerful precision in detecting aluminum alloys, upgrading zorba and separating magnesium fractions to create furnace-ready aluminum. Scrap metal recyclers and smelters alike can profit from TOMRA’s in-house developed mechanics, sensors and software that maximize yields and purity levels.

In this video, our customer Alutrade reveals the extraordinary results they have achieved with the new X-TRACT™. As the largest UK independent aluminum recycler, the company processes more than 42,000 metric tons of aluminum scrap per year. Whether recycling aluminum cans, manufacturing scraps (extrusions) or zorba processing, the new generation X-TRACT™ is the ideal sorting system for peak performance.

Explore now: www.tomra.com/xtract