Seeing is believing.

Welcome to our TOMRA video channel. Browse, share and embed videos from the TOMRA universe!

If you don’t want to miss any new video, please subscribe to our video channel.

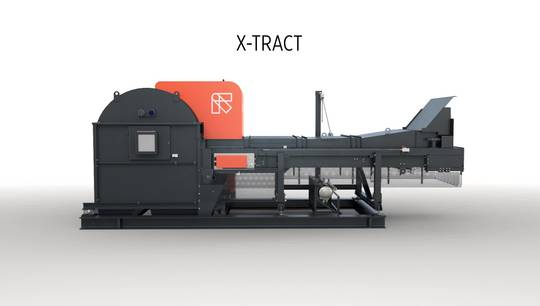

Aluminum Recycling – High Purity Aluminum Sorting with New X-TRACT

High purity and high recovery sorting of aluminum with the new TOMRA X-TRACT featuring high-speed x-ray transmission (XRT) technology. Meet the future of aluminum recycling.

Discover the new generation X-TRACT for metal sorting: www.tomra.com/xtract

TOMRA is a global leader in enabling aluminum recycling and processing with XRT sorting systems installed in 34 countries. The newest generation X-TRACT combines our proven design concept and groundbreaking features that accelerate the production of clean fractions for low-carbon aluminum.

X-TRACT’s new x-ray setup allows operators to adjust sorting to their needs and input material by separating aluminum from super lights and heavy metals at high throughput speeds. With increased belt speeds up to 3.8 meters per second and increased capacity per meter width, the new X-TRACT accelerates the recovery of green aluminum and secondary metals like copper wires.

With powerful precision in detecting aluminum alloys containing heavy metal and improved separation of magnesium, new X-TRACT creates furnace-ready aluminum fractions that meet even the most demanding quality requirements. Scrap metal recyclers and smelters profit from TOMRA’s in-house developed mechanics, sensors and software that maximize yields and purity levels.

Whether recycling aluminum cans, window profiles or end-of-life vehicles, the new generation X-TRACT is the ideal sorting system for long-lasting performance.

Explore X-TRACT’s newest features now: www.tomra.com/xtract

Discover the new generation X-TRACT for metal sorting: www.tomra.com/xtract

TOMRA is a global leader in enabling aluminum recycling and processing with XRT sorting systems installed in 34 countries. The newest generation X-TRACT combines our proven design concept and groundbreaking features that accelerate the production of clean fractions for low-carbon aluminum.

X-TRACT’s new x-ray setup allows operators to adjust sorting to their needs and input material by separating aluminum from super lights and heavy metals at high throughput speeds. With increased belt speeds up to 3.8 meters per second and increased capacity per meter width, the new X-TRACT accelerates the recovery of green aluminum and secondary metals like copper wires.

With powerful precision in detecting aluminum alloys containing heavy metal and improved separation of magnesium, new X-TRACT creates furnace-ready aluminum fractions that meet even the most demanding quality requirements. Scrap metal recyclers and smelters profit from TOMRA’s in-house developed mechanics, sensors and software that maximize yields and purity levels.

Whether recycling aluminum cans, window profiles or end-of-life vehicles, the new generation X-TRACT is the ideal sorting system for long-lasting performance.

Explore X-TRACT’s newest features now: www.tomra.com/xtract