Seeing is believing.

Welcome to our TOMRA video channel. Browse, share and embed videos from the TOMRA universe!

If you don’t want to miss any new video, please subscribe to our video channel.

Recovering MDF from waste wood – GAIN deep learning technology

Recovering MDF from waste wood with GAIN deep learning technology creates high-quality wood chips for

fiber-based products and packaging. In addition to sorting Wood A (non-processed) from Wood B (processed), GAIN goes the extra mile to separate MDF into mono fractions for recycling.

Learn more about GAIN for wood chip sorting: solutions.tomra.com

Until recently, waste MDF was typically sent to incinerators or landfills. Innovative processing techniques for waste wood, including the recovery of wood fibers from MDF, offer numerous industries the opportunity to increase sustainability through recycled wood.

The wood-based panel industry, for example, is leading effort by sorting non-processed (Wood A) from processed (Wood B) waste wood to use in the production of chipboards. Additional sorting to separate MDF from other processed woods, creates an addition fraction that can be processed and recycled.

TOMRA wood sorting solutions for high-quality material recycling consists of two sorting units:

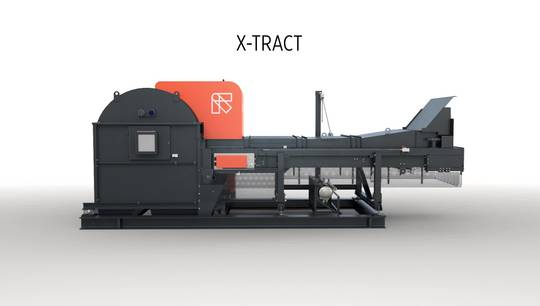

X-TRACT delivers high-throughput sorting of mixed materials to remove inert materials, glass, metals, and other impurities from waste wood.

AUTOSORT with the add-on GAIN technology enables your operation to create clean recycled wood chip fractions and differentiate between non-processed wood (Wood A) and processed wood (Wood B). GAIN uses deep learning technology to instantly differentiate and identify different types of processed woods to produce single fractions of clean wood and MDF.

With TOMRA waste wood sorting solutions, you benefit from:

- High throughput and fast processing

- Maximum yield and high purity levels

- Increased process control

- Robust and flexible sorting systems

- A partner with industry expertise at your side